SICURVITE lock for TIM Operator

Key Features

- High-quality materials and construction

- Industry standard compliance

- Rigorous quality testing

Understanding MPO Connectivity for High-Density Fiber Networks

In fiber optic terminology, MPO stands for Multi-fiber Push-On, a standardized connector system designed to accommodate multiple fibers in a single interface. This technology addresses critical B2B challenges in telecommunications infrastructure by enabling unprecedented port density, reducing installation time by up to 70% compared to individual LC connectors, and minimizing connection points that can compromise network reliability.

Technical Specifications

| Specification | Value |

|---|---|

| Connector Type | MPO-12 (Female) |

| Insertion Loss | ≤0.35 dB |

| Return Loss | ≥55 dB (PC), ≥60 dB (APC) |

| Operating Temperature | -40°C to +85°C |

| Durability | 500 mating cycles |

| Compliance Standards | IEC 61754-7, TIA/EIA-604-18, RoHS |

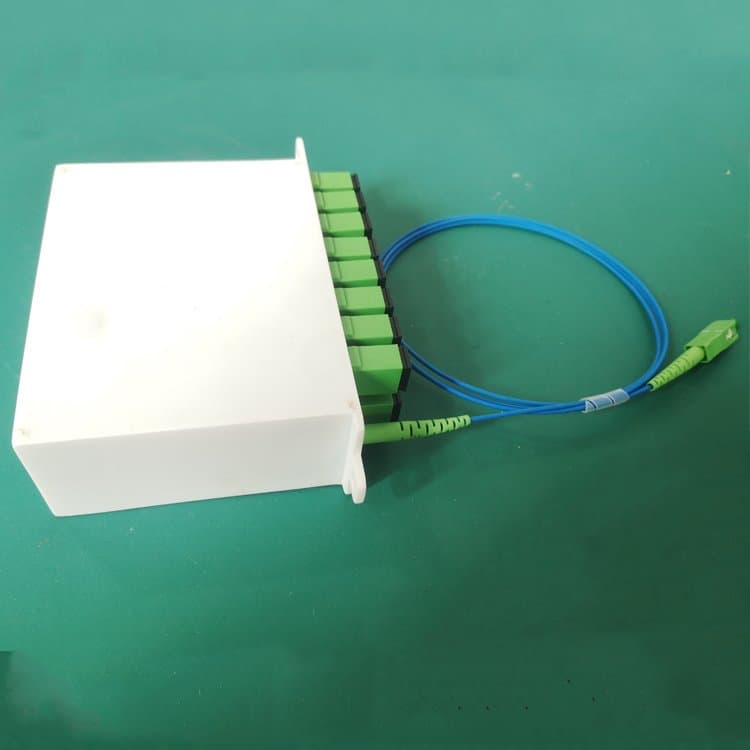

Engineered for TIM Operator Requirements

The SICURVITE lock mechanism provides secure MPO connections specifically designed for Telecommunications Infrastructure Management (TIM) applications. Our precision-engineered components eliminate accidental disconnections in high-vibration environments while maintaining the rapid deployment advantages of MPO technology. The corrosion-resistant housing ensures long-term performance in diverse climatic conditions.

Telhua Engineer's Tip

When deploying MPO connectors in high-density configurations, ensure proper polarity alignment by using our key-up to key-down methodology. This prevents signal reversal in parallel optic applications and maintains consistent A-B polarity across your entire fiber plant. For 40G/100G deployments, verify that your MPO cables are factory-terminated with precise 0.75mm pitch alignment to avoid modal dispersion issues.

Standards Compliance & Quality Assurance

All Telhua MPO components undergo rigorous testing to exceed IEC 61300-3-34 for insertion loss stability and TIA/EIA-455-171 for environmental performance. Our RoHS-compliant manufacturing process ensures environmental responsibility without compromising the mechanical integrity required for carrier-grade installations. Each connector is individually tested and serialized for complete traceability.