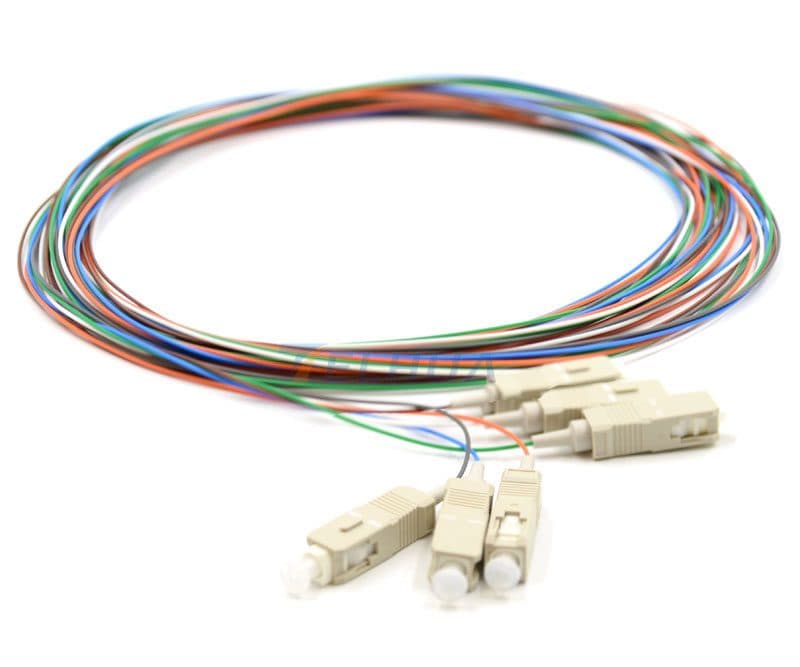

SCPC OM1 Fiber Optic Pigtail

Key Features

- High-quality materials and construction

- Industry standard compliance

- Rigorous quality testing

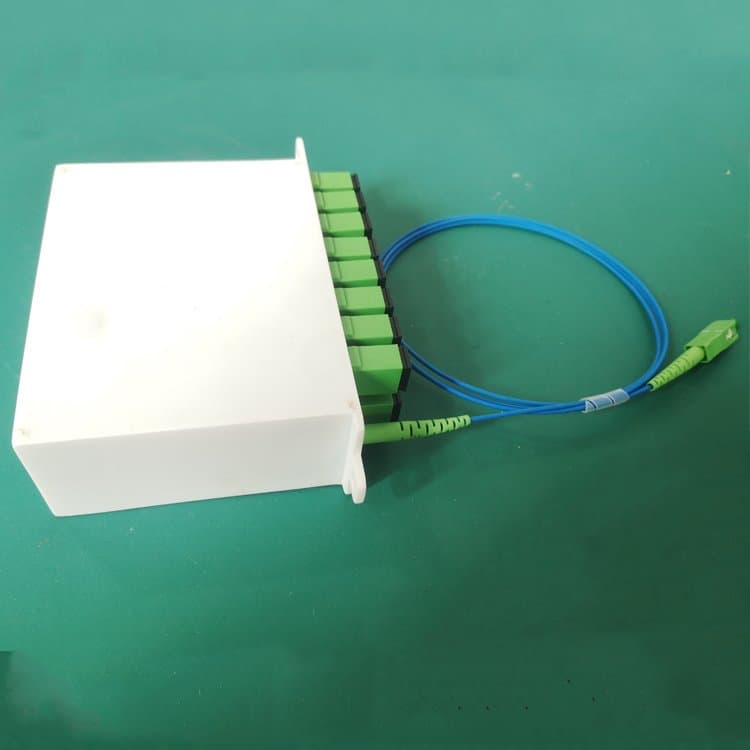

Optimize Your Fiber Optic Infrastructure with High-Density Connectivity

In high-density data center and enterprise network environments, inefficient fiber optic cable core management leads to installation delays, increased risk of signal degradation, and compromised reliability. The Telhua SCPC OM1 Fiber Optic Pigtail addresses these critical B2B pain points by delivering precise, factory-terminated connectivity that streamlines deployment while ensuring consistent optical performance.

Technical Specifications

| Specification | Value |

|---|---|

| Fiber Type | OM1 62.5/125μm Multimode |

| Connector Type | SCPC (Simplex) |

| Cable Type | 900μm Tight Buffer |

| Insertion Loss | ≤0.3 dB |

| Return Loss | ≥35 dB (PC), ≥50 dB (UPC), ≥60 dB (APC) |

| Operating Temperature | -40°C to +75°C |

| Flammability Rating | IEC 60332-1, RoHS Compliant |

| Standards Compliance | TIA/EIA-568, IEC 61754, RoHS |

Engineered for Reliability and Installation Efficiency

Our SCPC OM1 pigtails feature precision ceramic ferrules and rigorous factory testing to eliminate field termination errors. The 900μm tight buffer design provides superior mechanical protection for the fiber optic cable core, reducing breakage during high-density installations. Each unit undergoes 100% optical performance verification to ensure compliance with industry standards.

Telhua Engineer's Tip

For optimal performance in OM1 multimode applications up to 1GbE, ensure proper fiber optic cable core alignment by using our SCPC connectors with matching adapters. The 62.5/125μm fiber geometry requires precise ferrule polishing to minimize modal dispersion—our factory-terminated pigtails maintain consistent core alignment within 1μm tolerance, preventing the signal attenuation commonly seen in field-terminated solutions.

Standards Compliance and Quality Assurance

All Telhua SCPC OM1 Fiber Optic Pigtails comply with TIA/EIA-568 for structured cabling, IEC standards for optical performance, and RoHS directives for environmental safety. Our manufacturing process includes automated polishing and interferometric inspection to guarantee every connector meets exacting specifications for insertion loss and return loss.