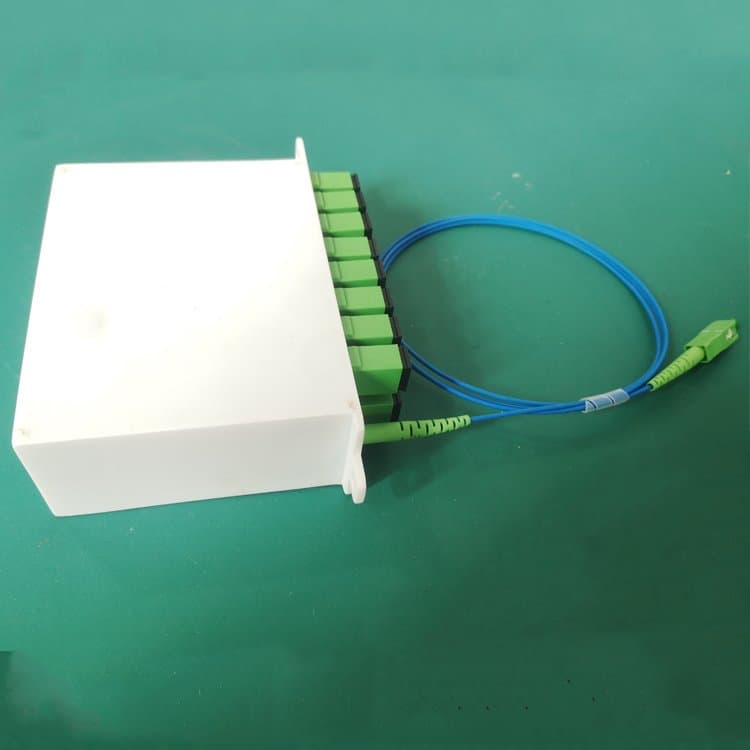

SCAPC Plastic Fiber Optic Attenuator

Key Features

- High-quality materials and construction

- Industry standard compliance

- Rigorous quality testing

Optimize Your Fiber Optic Patch Panel Density with Precision Attenuation

Integrating fixed optical attenuators into high-density fiber optic patch panels presents significant challenges for network engineers. The Telhua SCAPC Plastic Fiber Optic Attenuator is engineered specifically to overcome these obstacles, providing reliable signal management without compromising valuable rack space or installation efficiency.

Engineered for High-Density Network Environments

Traditional attenuation solutions often create bulk and cable management issues in constrained patch panel setups. The SCAPC attenuator's compact, polymer-based design enables seamless integration alongside standard connectors, maintaining optimal port density. Its precision-molded construction ensures consistent performance across thousands of insertion cycles, addressing critical reliability concerns in mission-critical data centers and telecom hubs.

Telhua Engineer's Tip: Managing Modal Noise in Multi-Mode Systems

When deploying fixed attenuators in legacy multi-mode fiber systems, improper attenuation can induce modal noise—a common but often overlooked performance degradation. The SCAPC's carefully calibrated attenuation profile minimizes phase distortion across propagation modes. For optimal results in 50μm OM3/OM4 environments, install attenuators closest to the receiver and maintain bend radius above 15mm post-installation to preserve modal distribution integrity.

Technical Specifications

| Specification | Value |

|---|---|

| Connector Type | SC/APC (Angled Physical Contact) |

| Attenuation Values | 1dB, 3dB, 5dB, 10dB, 15dB, 20dB |

| Operating Wavelength | 1260-1650nm |

| Insertion Loss | <0.5dB |

| Return Loss | >55dB |

| Operating Temperature | -40°C to +75°C |

| Durability | >500 mating cycles |

| Compliance Standards | IEC 61753-1, TIA/EIA-568-C.3, RoHS |

Standards Compliance and Quality Assurance

Every SCAPC Plastic Fiber Optic Attenuator undergoes rigorous testing to ensure compliance with international standards. The product meets IEC 61753-1 performance requirements for Category C (controlled environment) applications and aligns with TIA/EIA-568-C.3 specifications for optical fiber cabling components. Manufactured with RoHS-compliant materials, our attenuators support sustainable infrastructure initiatives while delivering uncompromising performance.

Installation Efficiency for Network Upgrades

Network expansion and technology refresh cycles demand rapid, error-free component installation. The SCAPC attenuator's keyed APC connector design prevents rotational misalignment, reducing installation time by up to 40% compared to non-keyed alternatives. This precision engineering minimizes the risk of connector end-face damage during high-volume deployments, particularly valuable when retrofitting existing fiber optic patch panel installations.