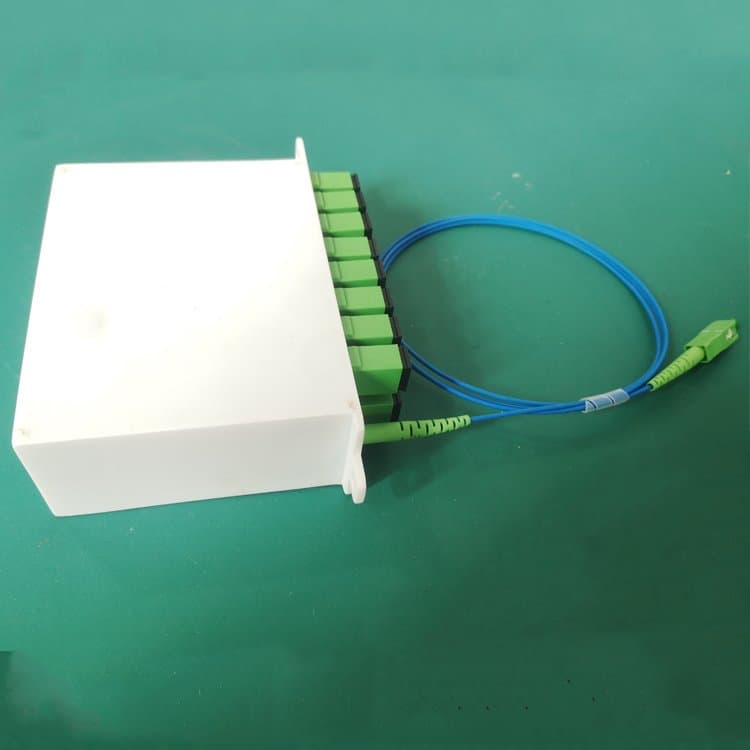

Outdoor telecommunication enclosure

Key Features

- High-quality materials and construction

- Industry standard compliance

- Rigorous quality testing

Engineered for Demanding Outdoor Telecommunications

Telhua's outdoor telecommunication enclosure provides a robust, weatherproof housing solution for fiber optic splices, terminations, and passive components in harsh environments. Designed to meet the rigorous demands of telecommunications infrastructure, this enclosure ensures reliable performance while addressing critical B2B pain points like installation efficiency, space optimization, and long-term durability.

Key Features and Benefits

Superior Environmental Protection

With an IP68 rating and corrosion-resistant materials, our enclosure withstands extreme temperatures, moisture, UV exposure, and physical impacts, minimizing maintenance needs and downtime.

High-Density Fiber Management

Optimized internal design supports high fiber counts in a compact footprint, addressing space constraints without compromising accessibility or future scalability.

Rapid Deployment

Pre-assembled components and tool-less access panels reduce installation time by up to 40%, accelerating network rollout and lowering labor costs.

Technical Specifications

| Specification | Value |

|---|---|

| Ingress Protection | IP68 |

| Operating Temperature | -40°C to +85°C |

| Fiber Capacity | Up to 144 fibers |

| Material | UV-stabilized polycarbonate |

| Dimensions (H×W×D) | 400×300×150 mm |

| Mounting Options | Pole, wall, or strand |

| Compliance | IEC 60529, TIA/EIA-568, RoHS |

Telhua Engineer's Tip

For optimal thermal management in direct sunlight, orient the enclosure so ventilation slots face north/south to minimize solar heat gain. This simple alignment can reduce internal temperature by 5-8°C, extending component lifespan and maintaining signal integrity in high-density configurations.

Standards and Compliance

This product is engineered to meet international standards including IEC 60529 for ingress protection, TIA/EIA-568 for telecommunications infrastructure, and RoHS for environmental safety. Regular third-party testing ensures consistent compliance across all production batches.