Generic Splice Patch Shelf Trays FIST-GPST

Product Parameters

- Drawer Open Way:Sliding

- Material:Metal

- No. of U:3U

Optimize Fiber Network Density with Professional Splice Management

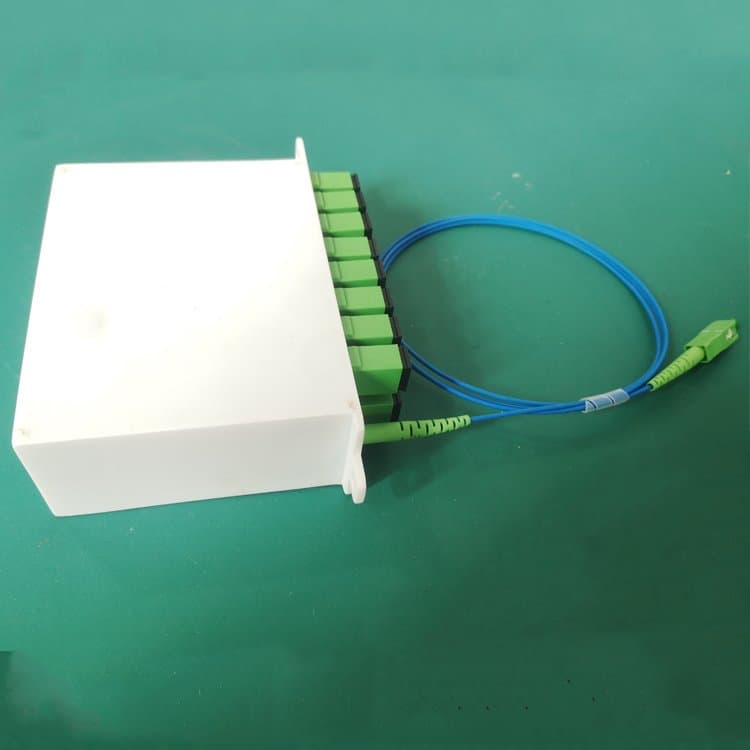

Telhua's Generic Splice Patch Shelf Trays (FIST-GPST) provide a robust, scalable solution for organizing and protecting fiber optic splices in high-density rack environments. Engineered for telecommunications, data centers, and enterprise networks, these trays maximize rack space utilization while ensuring long-term splice integrity and easy access for maintenance.

Key Features for Demanding B2B Applications

High-Density, Modular Design

Our trays are designed to maximize port density within standard 19" or 23" rack units, allowing you to consolidate more splices in less space. The modular architecture supports flexible configuration and future expansion without requiring complete system overhauls.

Enhanced Reliability and Protection

Built with durable, flame-retardant materials, each tray features secure splice holder modules that protect delicate fusion splices from dust, bending, and physical stress. This design minimizes signal loss and prevents network downtime caused by splice failure.

Streamlined Installation and Maintenance

The intuitive, tool-accessible design enables rapid deployment and easy re-entry for splicing or testing. Clear labeling areas and organized routing channels reduce installation time and simplify ongoing network management, lowering total cost of ownership.

Technical Specifications

| Specification | Detail |

|---|---|

| Model | FIST-GPST |

| Compatibility | Standard 19" / 23" Rack Mount |

| Material | Flame-Retardant ABS/PC Alloy |

| Splice Capacity | Configurable, typically 12-24 splices per tray |

| Fiber Management | Integrated routing channels and slack storage |

| Operating Temperature | -40°C to +85°C |

| Standards Compliance | IEC 61753-1, TIA/EIA-568, RoHS |

Telhua Engineer's Tip

For optimal performance in high-vibration environments, such as industrial settings or mobile deployments, apply a small amount of gel sealant at the splice holder entry points after inserting the splice sleeves. This creates a secondary moisture barrier and dampens micro-vibrations that can gradually degrade splice performance over time, a consideration beyond standard environmental sealing.