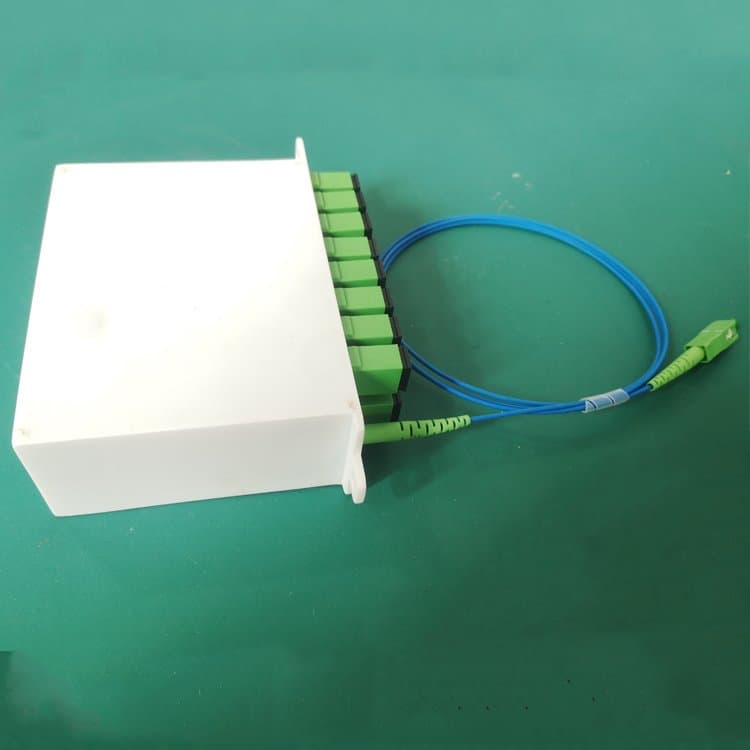

FCAPC Fiber Optic Pigtail WITH 12 COLOR

Key Features

- High-quality materials and construction

- Industry standard compliance

- Rigorous quality testing

High-Density 12-Core Fiber Optic Pigtail Solution

Telhua's FCAPC Fiber Optic Pigtail with 12 Color is engineered for B2B network deployments demanding maximum fiber density without compromising reliability. This pre-terminated solution eliminates field termination errors, accelerates installation timelines, and ensures consistent optical performance in data centers, enterprise backbones, and telecommunications infrastructure.

Optimized for Critical Infrastructure

Our 12-core fiber cable pigtail addresses the core challenges faced by network engineers and installers:

- Space Efficiency: Achieve higher port density in patch panels and enclosures, reducing physical footprint and hardware costs.

- Installation Speed: Pre-polished connectors and factory-tested assemblies cut deployment time by up to 70% compared to field termination.

- Signal Integrity: Precision ceramic ferrules and angled physical contact (APC) polishing minimize back reflection (<-65dB) for stable transmission in high-speed networks.

- Color-Coded Management: 12 distinct buffer tube colors (TIA-598-D compliant) enable rapid identification and reduce cross-connection errors during maintenance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Fiber Type | Single-mode (G.652.D) or Multimode (OM3/OM4) |

| Core Count | 12 fibers |

| Connector Type | FC/APC (Angled Physical Contact) |

| Cable Diameter | 2.0mm ±0.1mm (900μm tight buffer) |

| Insertion Loss | ≤0.3dB (typical 0.2dB) |

| Return Loss | ≥65dB (APC) |

| Operating Temperature | -40°C to +85°C |

| Standards Compliance | IEC 61754-4, TIA/EIA-604-4, RoHS 3 |

Telhua Engineer's Tip

When deploying high-count fiber arrays, thermal expansion mismatch between cable jackets and patch panel materials can induce microbending loss over time. Our FCAPC pigtails incorporate a proprietary stress-relief boot design that maintains 0.5mm minimum bend radius while accommodating ±15° axial movement, preventing performance degradation in temperature-fluctuating environments. For optimal results in vertical riser applications, install with alternating clockwise/counterclockwise slack loops every 15 meters.