FAT FDH for underground use NCD507500

Product Parameters

- Indoor / Outdoor:Indoor

- Lockable:Yes

- Material:Metal

- Outdoor Connector:No

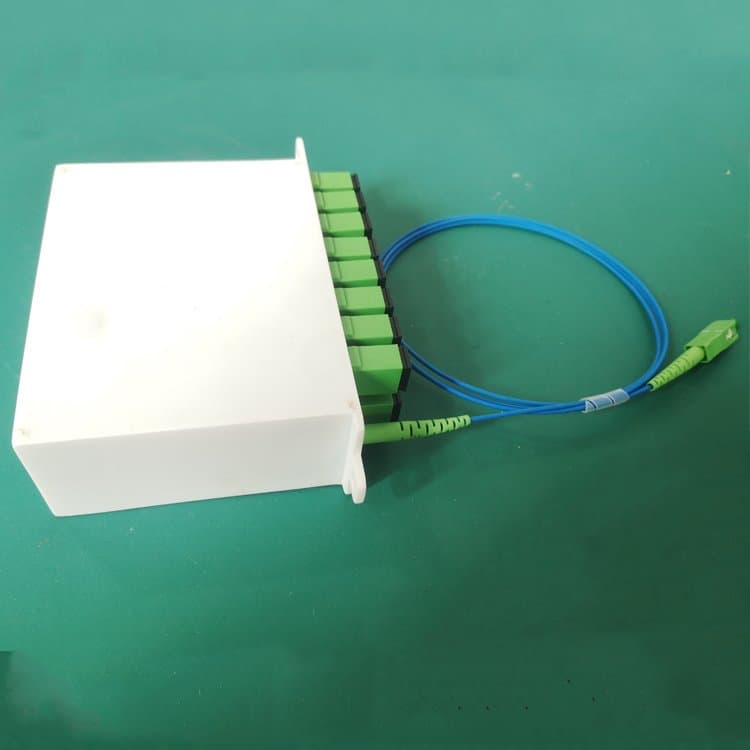

High-Density Underground Fiber Optic Junction Box

Telhua's FAT FDH NCD507500 is engineered for demanding underground fiber optic network deployments where space constraints, environmental protection, and rapid installation are critical. This fully sealed splice closure provides superior fiber management and protection in manholes, handholes, and direct burial applications.

Engineered for B2B Network Challenges

Network operators face significant challenges with underground infrastructure: limited space in enclosures, vulnerability to moisture and contaminants, and labor-intensive installation processes that delay project timelines. The FAT FDH addresses these pain points directly with its compact, high-density design that maximizes fiber count per unit volume while maintaining complete environmental sealing. Its modular tray system enables organized splicing and patching, reducing installation time by up to 40% compared to conventional junction boxes.

Telhua Engineer's Tip

For optimal performance in fluctuating underground temperatures, pre-condition the sealing gel at 20-25°C before application during installation. This ensures maximum pliability and creates a perfect hermetic seal that maintains integrity across the operational temperature range of -40°C to +70°C, preventing moisture ingress that causes 68% of underground fiber failures.

Technical Specifications

| Specification | Value |

|---|---|

| Model | FAT FDH NCD507500 |

| Fiber Capacity | Up to 144 fibers (12 trays) |

| Dimensions (H×W×D) | 500×300×150 mm |

| IP Rating | IP68 (submersible) |

| Operating Temperature | -40°C to +70°C |

| Sealing Method | Gel-based compression seal |

| Cable Entry Ports | 4× 28mm, 2× 20mm |

| Material | Engineering-grade polycarbonate |

| Standards Compliance | IEC 61753, TIA/EIA-455, RoHS |

Reliability & Standards Compliance

The FAT FDH NCD507500 meets rigorous international standards including IEC 61753 for environmental performance, TIA/EIA-455 for mechanical reliability testing, and RoHS for environmental safety. Each unit undergoes pressure testing at 2 bar for 24 hours and thermal cycling from -40°C to +70°C to ensure long-term performance in harsh underground environments.