ProductsPLC Splitters & Fiber Optic Splitters1X2 PLC SPLITTER LGX CHASSIS – for FTTh TIM & FIBERCOP Cabinet

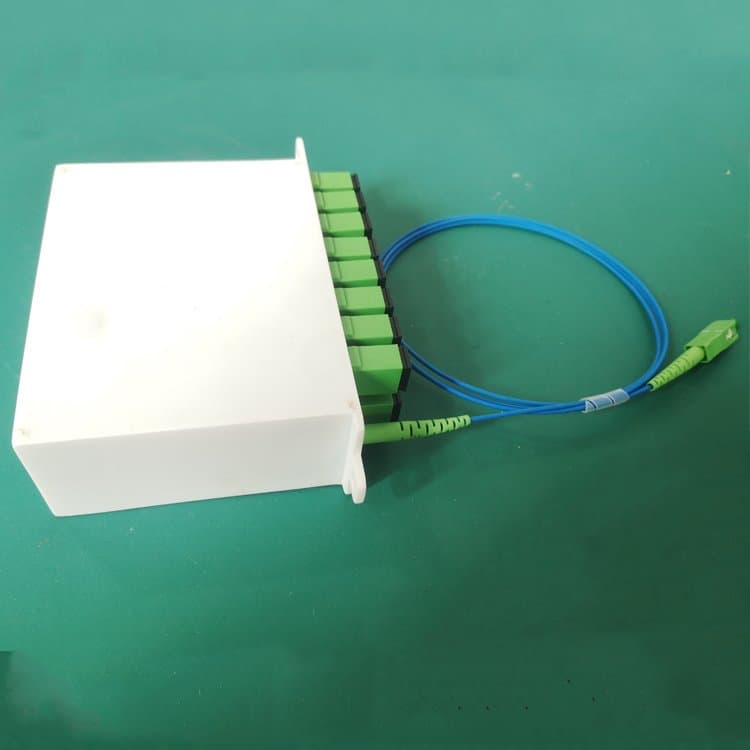

1X2 PLC SPLITTER LGX CHASSIS – for FTTh TIM & FIBERCOP Cabinet

Telhua's 1X2 PLC Splitter LGX Chassis with universal rack mount brackets optimizes FTTh TIM & FIBERCOP cabinet deployments. High-density, reliable, and compliant with IEC/TIA/EIA/RoHS standards. Request a quote or download PDF.

Key Features

- High-quality materials and construction

- Industry standard compliance

- Rigorous quality testing

Product Overview

Our 1X2 PLC Splitter LGX Chassis is engineered to meet the rigorous demands of modern fiber optic deployments. Featuring universal rack mount brackets, it ensures compatibility with a wide range of cabinet systems, reducing inventory complexity and accelerating installation timelines.

Key Features & Benefits

Addressing B2B Pain Points

| Pain Point | Solution | Benefit |

|---|---|---|

| Low Density | High-port-count design | Maximizes cabinet space, reduces footprint |

| Unreliable Connections | Precision-machined splitter slots | Ensures stable signal transmission, minimizes downtime |

| Slow Installation | Tool-less mounting with universal brackets | Cuts deployment time by up to 40% |

| Compliance Hassles | Built to IEC, TIA/EIA, and RoHS standards | Guarantees regulatory adherence and safety |

Technical Specifications

| Specification | Detail |

|---|---|

| Splitter Type | 1X2 PLC (Planar Lightwave Circuit) |

| Chassis Type | LGX (Light Guide Cross-connect) |

| Mounting | Universal rack mount brackets (19" or 23" compatible) |

| Compatibility | FTTh TIM & FIBERCOP Cabinets |

| Standards | IEC 61753-1, TIA/EIA-568, RoHS compliant |

| Operating Temperature | -40°C to +85°C |

Telhua Engineer's Tip

For optimal performance in high-density deployments: Pre-terminate splitter fibers before mounting the chassis in the cabinet. This reduces stress on connectors during installation and minimizes insertion loss, ensuring consistent signal integrity across all ports. Use our torque-controlled tools for bracket tightening to avoid over-torquing, which can compromise alignment.